電話:0755-86131192

郵箱:info@3doe.com

地址:深圳市龍華區民治大道民治商會大廈六樓

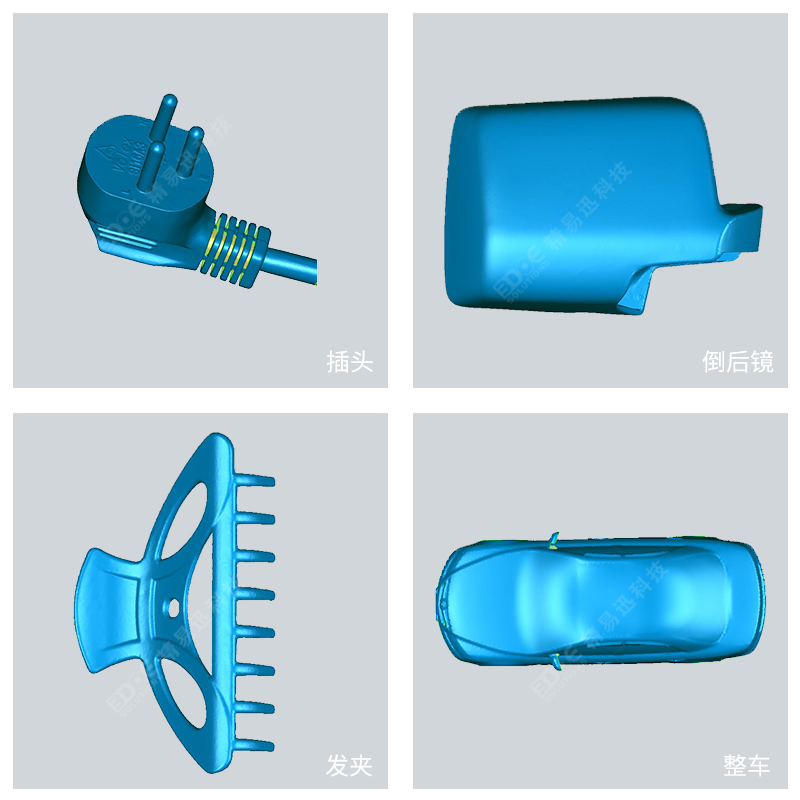

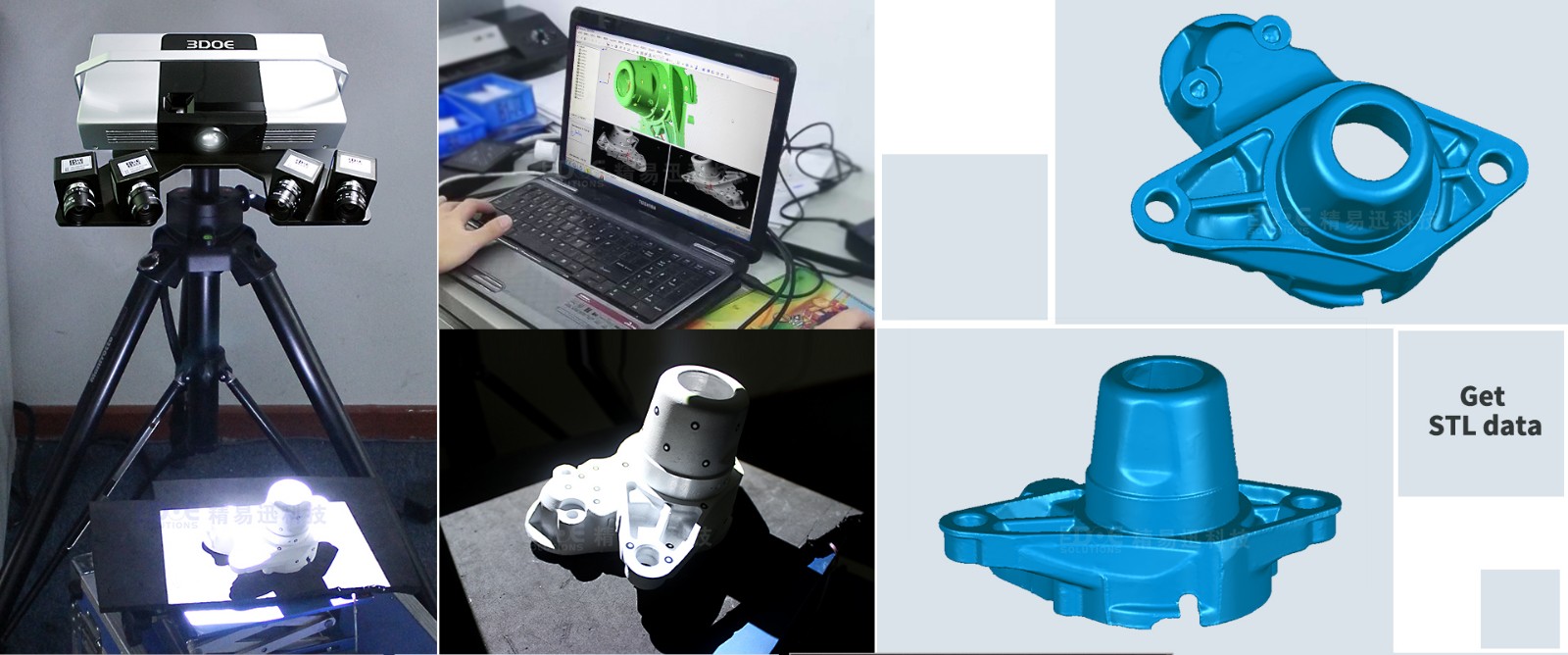

PTS-A series (four - eye) photographic 3D scanner is suitable for industrial design, reverse engineering and dimensional 3D detection projects, non-contact structural optical measurement, camera imported from Germany, independent research and development of supporting software, to obtain the 3D external contour of objects with high precision and stability. Successful solutions are applied in the following fields: reverse 3D scanning and 3D detection of molds, sheet metal parts, large-scale casting parts, oil-clay models, injection parts, sculpting parts, auto parts, etc. Difference between binocular and quadruocular: The position of the binocular camera is adjustable, and the binocular can also have multiple sets of scanning range. Switching the scanning range requires recalibration. The quaternary has two scanning ranges namely two sets. Scan range can be switched freely. For example, an object scanned for 4 meters and then scanned for 1.5 meters can directly switch the scanning range without adjusting the camera Angle and calibration.

The PTS-A series (four mesh) photo-type 3D scanner includes two sets of scanning range. Objects of different scan sizes do not need to be recalibrated, and the scanning range can be switched directly. It is suitable for industrial design, reverse engineering and dimensional 3D detection projects, non-contact structural optical measurement, camera imported from Germany, independent research and development of supporting software, obtaining 3D external contour of objects with high precision and stability.

Successful solutions are applied in the following fields : reverse 3D scanning and 3D detection of molds, sheet metal parts, large-scale casting parts, oil-clay models, injection parts, sculpting parts, auto parts, etc.

Difference between binocular and quadruocular :

Binocular : The camera position is adjustable or can have multiple sets of scanning range. Switching scanning range requires recalibration.

Four -eyes: It has two scanning ranges, namely two groups, which can be switched freely. For example, after scanning an object of 4 meters, an object of 1.5 meters can be changed directly without adjusting camera Angle and correction.

Product Features:

hardware

1) Equipped with two sets (4) 1.3 megapixel industrial cameras imported from Germany. Within 5 seconds, 130W point cloud data with uniform distribution can be obtained on the surface of the object, with accuracy ≤0.05mm;

2) The two groups of scanning ranges coexist. Objects with different scanning sizes do not need to be recalibrated, and the scanning range can be directly switched.

3) Non-contact (white light) raster scanning technology, suitable for soft and easily deformed objects measurement requirements.

4) The equipment is small in size, occupies little space and has no noise, which can be easily brought to the measurement site.

5) It can be used with tripod, mechanical arm and turntable, flexibly adjust the position of the scanner, and adapt to the scanning of heavy and unmovable objects.

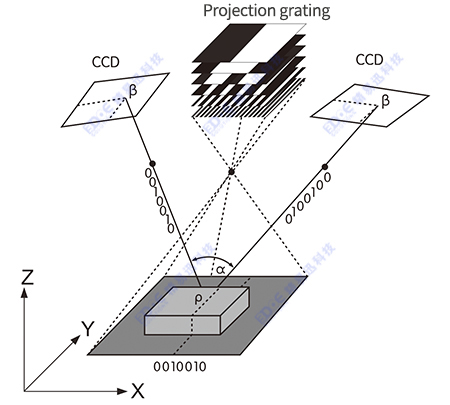

Photographic 3D scanner-measurement principle

The 3DOE 3D measuring head is composed of two high-resolution industrial CCD cameras on the left and right and a grating projection unit. The structured light measurement method is used to project a group of grating fringes with phase information onto the surface of the measured object using the grating projection unit. The two cameras on the left and right can measure simultaneously, and combine computer vision technology, photoelectric sensor technology, image processing technology and software control technology to obtain high-density three-dimensional data on the surface of the object in a very short time. The rotating object or scanning head is used to change the scanning angle of view. Based on the automatic splicing technology of multi-view point cloud, it can complete 360° scanning of the object in all directions.

Optional accessories

Automatic/manual turntable Calibration board Steering head Lifts

Developer Mark point Flight Case Tripod/Column

? Classic cases

3D scanning of castings

? Technical Parameters

Number of lenses | Four-eye type | |

Product number | PTS-A130-F400 | PTS-A130-F200 |

scanning method | Non-contact white light scanning | |

Single scan range (mm2) | 200 X150、400 X300 | 100X75、200 X150 |

Maximum measuring range (mm3) | 2000×1500×1500 | 1000 X750 X750 |

Measuring accuracy (mm) | 0.02~0.05 | 0.015~0.05 |

Single scan points (pixels) | 1,300,000×2 | |

Single scan speed | <5S | |

Average dot pitch (mm) | 0.07 ~ 0.3 | 0.04 ~ 0.15 |

Output file format | ASC, STL, OBJ, etc., can be connected with Geomagic, Imageware, 3Dmax, etc. | |

Splicing method | Automatic splicing of marked points, intelligent fusion into a single layer point cloud | |

? Application field

●Auto parts ●industrial design

●Reverse design(Scanner)

●Reverse design(Scanner)

●Mold design and inspection

●Mold design and inspection

●Craft Scan ●Wood carving scan

●Craft Scan ●Wood carving scan

●Game production

●Household appliances

●Electronic Products

●Teaching Research

●Cultural relics and archaeology

To understand the specific application, please feel free to consult online (message) or call 0755-86131192!

Provide system customized solutions!