電話:0755-86131192

郵箱:info@3doe.com

地址:深圳市龍華區民治大道民治商會大廈六樓

The 3D laser scanning head launched by 3DOE can collect millions of precise point data on any type of object surface, from matte black surface to highly reflective surface, even carbon fiber surface, without any special pretreatment, it is advanced, Widely applicable non-contact 3D laser scanning core equipment. It has the characteristics of wide applicability, large scanning range, high precision, fast speed and high cost performance.

The LM series 3D laser scanning head launched by 3DOE can collect millions of precise point data on the surface of any type of object, from matte black surface to highly reflective surface, even carbon fiber surface, without any special pretreatment, it is advanced The most widely applicable non-contact 3D laser scanning core equipment. It has the characteristics of wide applicability, large scanning range, high precision, fast speed and high cost performance.

1. Non-contact laser scanning: Avoid contact with the surface of the object, and can scan the surface of any type of object without pretreatment;

2. High measurement accuracy: high-precision laser scanning light source, with an accuracy of up to 0.05mm;

3. Fast scanning speed: the system can digitize tens of thousands of contour points per second, quickly and accurately obtain the complex three-dimensional data space of the measured object;

4. Simple operation: one-button automatic scanning mode, any object scanning without marking points;

5. Automatic splicing: no manual splicing required;

6. Flexible operation: the entire system supports multiple scans, and the fineness of the scan is adjustable, so that the overall shape can be quickly obtained, and the parts can be finely scanned;

7. Open interface: standard file interface, scanning software directly supports multiple data format files such as IGS, ASC, DXF, OBG, STL, WRL, VRML.

8. Wide applicability: It adopts advanced optical system design, strong anti-interference ability of ambient light, and can scan dark objects without pre-processing the objects. The measurement results can be output to CAD software in a variety of common file formats to generate digital models, and can be output to CAM software to generate cnc processing codes, helping users to achieve rapid copying and processing. It can be output to post-processing software to realize 3D model checking, product quality control, 3D measurement and other functions.

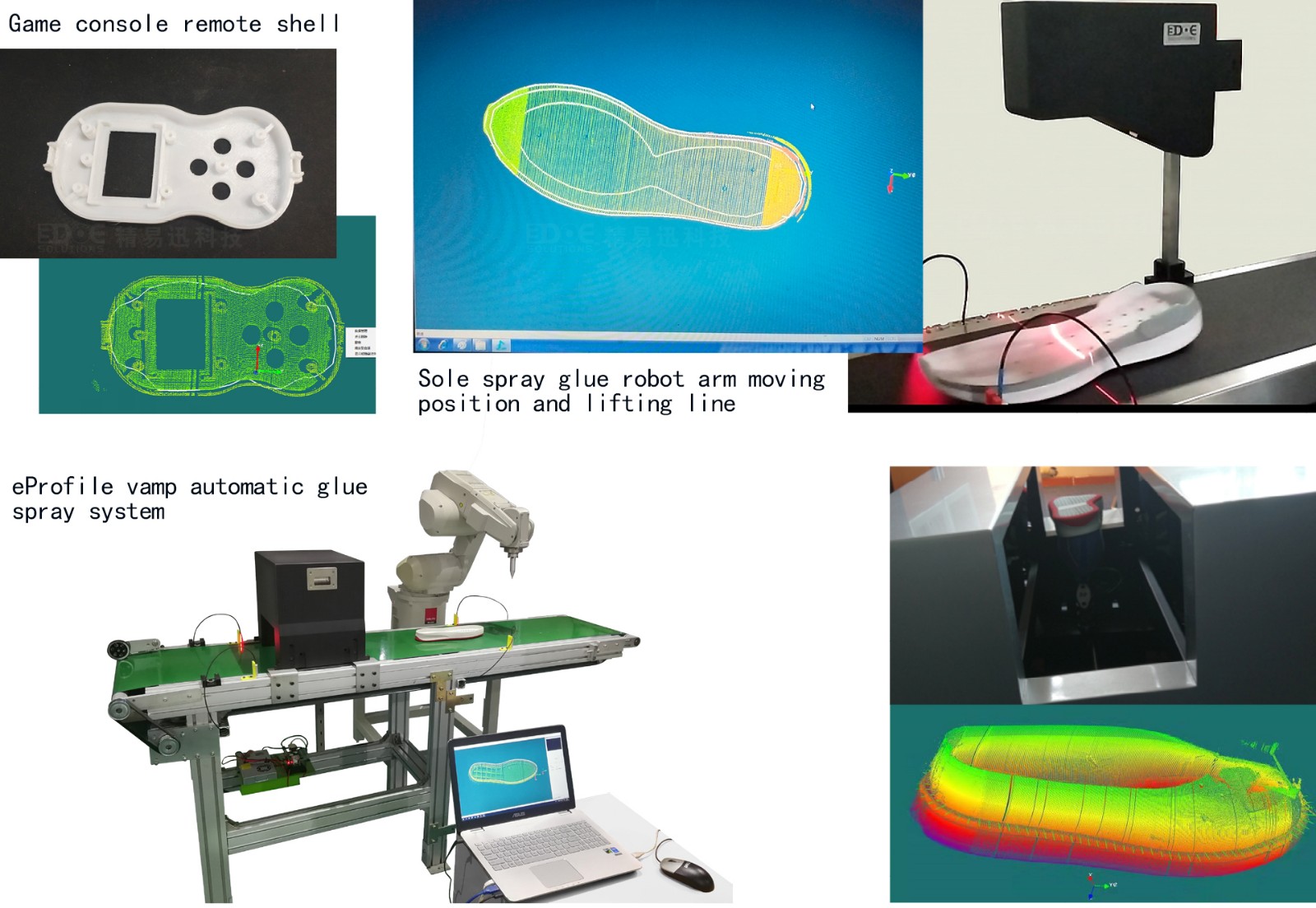

? Classic cases

? Technical Parameters

model | LMV1 | LMV2 | LMV4 | LMV6 | LMV8 |

X measuring range (mm) | 180 | 180 | 180 | 180 | 180 |

Z measuring range (mm) | 60 | 100 | 120 | 120 | 120 |

X-axis contour points | 1280-4096 | 2560 | 5120 | 7680 | 10240 |

Scanning speed (fps) | 100-600 | 210fps | 210 | 210 | 210 |

Repeatability (mm) | 0.01-0.05 | 0.02-0.05 | 0.05 | 0.05 | 0.05 |

Output Data | 3D point cloud data, automatic fusion of multi-view data, extraction of relevant contour lines and robot trajectory posture information | ||||

I/O interface | 3 programmable input interfaces, 3 programmable output interfaces | ||||

? Application field

☆ 3D visual positioning ☆ 3D defect detection ☆ Robot guidance, automated application

☆ Face measurement ☆ Digital application ☆ 3D vision related

To understand the specific application, please feel free to consult online (message) or

call 0755-86131192!

Provide system customized solutions!